With so many advanced technologies, many industries are manufacturing their parts more refinedly. Today, many industries produce heavy metals for manufacturing different types of metal products. To produce these heavy metal products, it is imperative to use only the best techniques. One such technique that most industries prefer is die casting. Automotive industries mainly use automotive parts die casting to produce the best castings. The most flexible automotive die casting solutions easily suit their configured setup.

Benefits of the die casting process

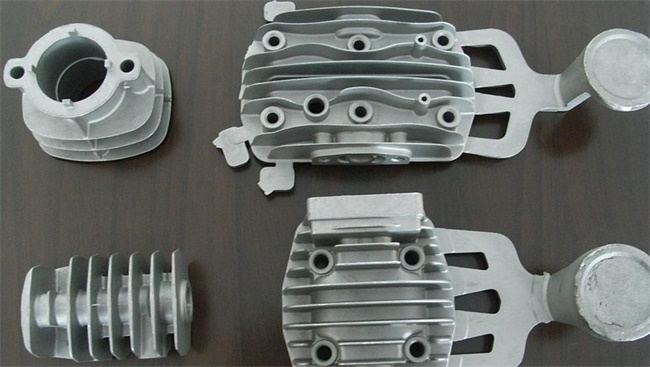

With the help of die casting, various products can be made. Especially in the automotive industry, die casting seems to be of great help. Die Casting uses molten metal that is pressurized to fill out the mold cavity. Raw metal is then heated and poured into the mold cavity. After cooling this molten metal, it is solidified to eject a newly created die casting. Die casting is a versatile process with its own set of advantages. Some of these benefits include:

- Die casting is such a process that can support multiple alloys and zinc. Usually, zinc is considered the most popular option for the die casting process. It is mainly because of the high strength and flexibility of zinc. Zinc is also quite inexpensive. So, the manufacturing of applications is quite large-scale. Some of the other alloys and metals supported in die casting are tin, copper, magnesium, aluminum, and lead.

- Automotive companies rely on die casting to get rid of any rigid or rough die casting. The pressured molten metals usually create smooth surfaces on the Casting. This solidified molten metal fills the void spaces out for a smoother outcome.

- There would be less or no finishing operation required for the process of die casting. Different types of casting processes need to be finished with the help of a machine. These are usually cumbersome and time-consuming. With die casting, you do not need either of these operations. Right after the die casting process is done, the manufactured products are shipped.

Manufacturing automotive parts with die casting

The automotive parts die casting process is making this industry more popular. The process overall is the same without any further complications. Die casting is known for making flexible and lightweight automotive parts. This process can manufacture every single component required in any vehicle. The components and structures that they make are pretty lightweight. Besides, they also manufacture eco-friendly components and do not cause any harm to the environment.