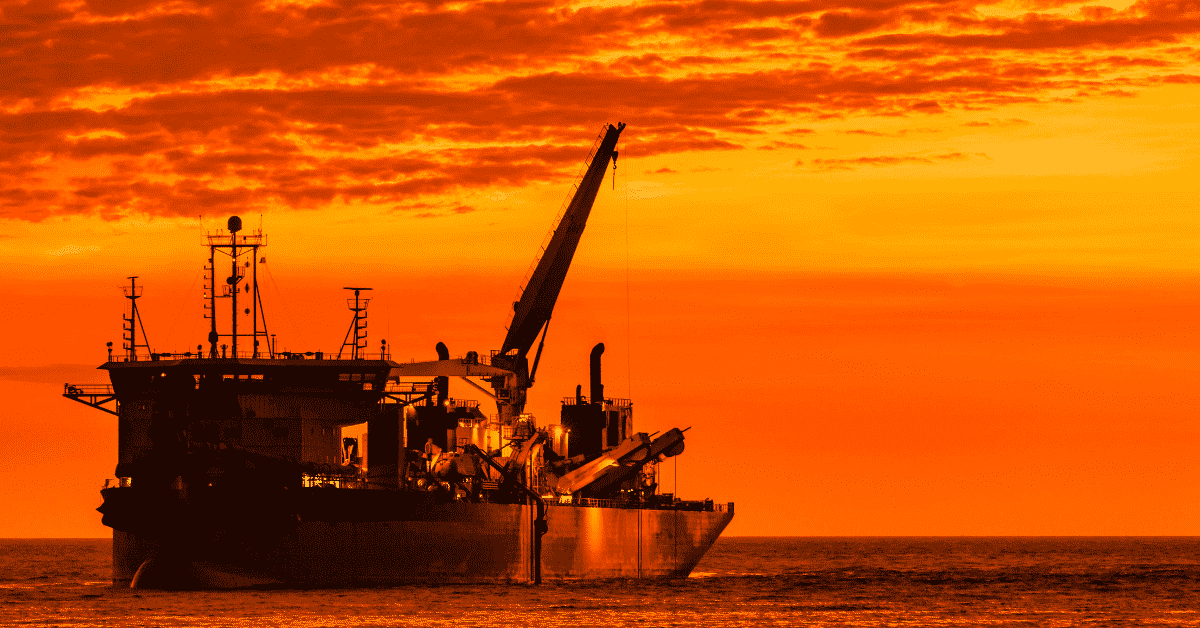

Offshore operations present unique challenges that require specialized lifting equipment to ensure safety and efficiency. Offshore lifting equipment plays a crucial role in various industries, including oil and gas, marine, and renewable energy sectors. This article explores the significance of offshore lifting equipment, highlighting its importance in maintaining safety, productivity, and operational excellence in offshore environments.

The Importance of Safety in Offshore Lifting Operations

Offshore lifting operations involve the movement of heavy loads, which can pose significant risks to personnel and equipment if not executed with utmost safety measures. Safety is paramount in offshore operations to protect workers, prevent accidents, and minimize downtime. The use of appropriate offshore lifting equipment is essential to ensure safe lifting, secure load handling, and compliance with stringent safety regulations. Implementing proper safety protocols, conducting regular equipment inspections, and providing comprehensive training are key to mitigating risks and fostering a safe offshore working environment.

Enhancing Efficiency through Offshore Lifting Equipment

Efficiency is a critical factor in offshore operations, where time and cost savings are crucial for project success. Offshore lifting equipment contributes to operational efficiency by streamlining lifting processes, reducing manual labor, and increasing productivity. Specialized equipment, such as cranes, winches, and hoists, enable the efficient movement of heavy loads, minimizing operational downtime and maximizing productivity. These equipment solutions are designed to withstand harsh offshore conditions, including extreme weather, corrosive environments, and challenging operational scenarios.

Furthermore, offshore lifting equipment incorporates advanced technologies, such as remote monitoring, automation, and precision controls, enabling precise load positioning and reducing human errors. Automated features and intelligent systems enhance operational efficiency by optimizing load handling, reducing cycle times, and improving overall workflow. These advancements improve project timelines, resource allocation, and overall operational effectiveness.

Key Considerations in Offshore Lifting Equipment Selection

Selecting the appropriate offshore lifting equipment is crucial for meeting project requirements, ensuring safety, and maximizing operational efficiency. Several factors should be considered during the selection process. These include the weight and dimensions of the loads to be lifted, the working environment, lifting capacity requirements, and the specific operational challenges.

Additionally, compliance with international standards and regulations, such as the International Organization for Standardization (ISO) and the American Petroleum Institute (API), is essential to guarantee the reliability and safety of the equipment. The equipment should be designed and certified to withstand the demanding offshore conditions, including corrosion resistance, robust construction, and adherence to relevant safety standards.

Routine inspection, maintenance, and testing of offshore lifting equipment are imperative to ensure ongoing safety and performance. Regular inspections by qualified personnel help identify potential issues, prevent equipment failures, and maintain compliance with safety standards.

Offshore lifting equipment is a vital component in ensuring safety and efficiency in offshore operations. By adhering to rigorous safety protocols, selecting the appropriate equipment, and maintaining regular inspections and maintenance, offshore industries can safeguard workers, enhance productivity, and achieve operational excellence in challenging offshore environments.