The introduction of 3D printers in the manufacturing industry has revolutionized how products are made. It has given businesses new flexibility in their production processes, allowing them to create highly customized products that were previously impossible or too costly to produce. The 3d printers singapore industry has overgrown in recent years, with companies such as Creatz3D at the forefront of this technological advancement.

The advantages of 3D printing over traditional manufacturing processes

3D printing, also known as additive manufacturing, is a process that involves building a 3D object from a digital model. The printer creates the object layer by layer, using various materials such as plastics, metals, and ceramics. This process eliminates many of the limitations of traditional manufacturing, such as the need for complex molds and tools. With 3D printing, businesses can produce highly customized products on demand without needing extensive inventories or long lead times.

One of the significant advantages of 3D printing is its ability to reduce costs. The traditional manufacturing process involves a lot of overheads, including tooling, labor, and inventory costs. With 3D printing, the need for tooling and molds is significantly reduced, significantly reducing production costs. This makes it an attractive option for businesses looking to reduce costs while maintaining a high level of quality.

Another significant advantage of 3D printing is its ability to improve product design. With traditional manufacturing, designers are limited by the manufacturing process and the materials used. With 3D printing, designers can create highly complex and intricate designs that were previously impossible. This opens up new possibilities for product design and innovation, allowing businesses to differentiate themselves from their competitors.

Printing service providers

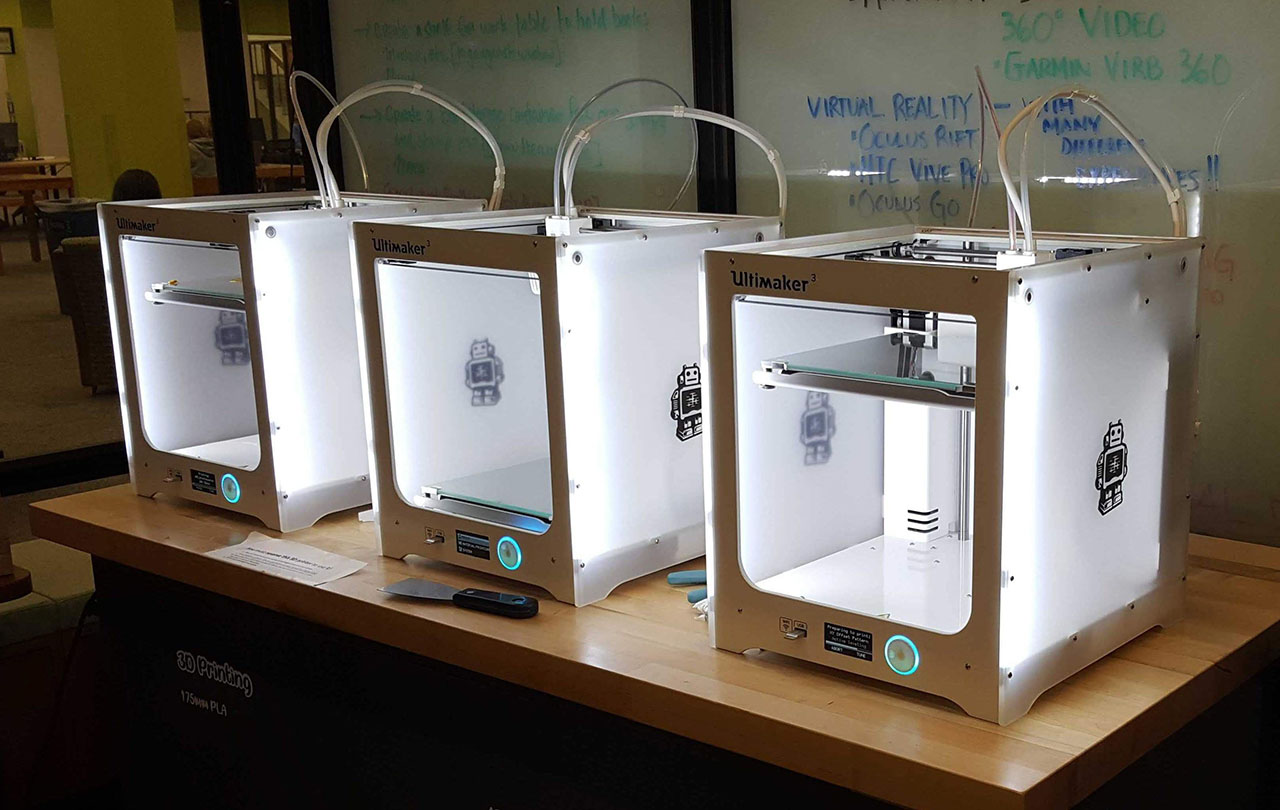

Creatz3D is one of the leading 3D printing service providers in Singapore. They offer various 3D printing solutions, including 3D printers, materials, software, and support services. They have helped many businesses in Singapore to adopt 3D printing technology, allowing them to improve their production processes and reduce costs.

Furthermore, 3D printing can potentially transform the supply chain and logistics industry. With 3D printing, products can be produced on demand and in small batches, eliminating the need for long lead times and expensive warehousing. This can result in significant business cost savings and reduced carbon emissions from transporting and storing goods.

Another emerging trend in the 3D printing industry is using advanced materials. In addition to traditional materials like plastics and metals, researchers are exploring the use of advanced materials like carbon fiber, ceramics, and even living cells. This opens up new possibilities for manufacturing products in a wide range of industries.

Lastly, 3D printing has the potential to revolutionize the construction industry. Researchers are exploring using 3D printing technology to create entire buildings and structures, significantly reducing construction times and costs. This can potentially transform how we build homes, buildings, and even entire cities.

Conclusion

In conclusion, 3D printing technology has revolutionized the manufacturing industry, providing businesses with new levels of flexibility and customization. In Singapore, companies such as Creatz3D are leading the way in adopting this technology and providing businesses with the tools and support they need to succeed. As the 3D printing industry continues to evolve, we expect to see further advancements that will transform how we design, create, and produce products.